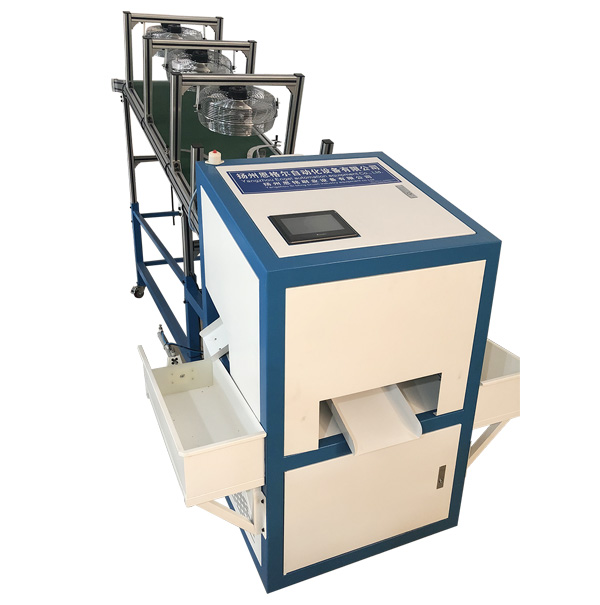

Yangzhou engel automation equipment co., LTD. High-speed toothbrush planting machine automatic processing:

High speed toothbrush planting machine teaching data sequence is the processing of the order, so teach as far as possible to teach the hole spacing minimum. Toothbrush flocking machine teach data can be horizontal, vertical can also teach, the order of the number of the above identification number is taught, that teach the shortest distance between two points, the motor running time of the shortest, run by an electric motor, mechanical shock will also reduce, flocking or drilling route serpentine, if possible, the number of the configuration make the first hole close to the last hole location, speed will be faster and more efficient.

Teaching plane rotation and teachings about, rotate to note that the teaching of the workpiece is moved to 360 degrees, had better not continue forward, inversion of teaching data, thus with planar similar teachings, if continue to forward teaching, this teaching data is increased continuously, the last hole location and the first hole distance is very big, suppose 20, when to finish the last hole, when to return to the first hole motor to turn 20 turn, turn speed is 15 per second, minimum need to 2 seconds, than positive &negative teach a product run 2 seconds, far beyond the output of a day. So the teaching should first work out the order of processing hole, find out the best method, can make the production efficiency.

Enter the teaching screen, you must press "back to zero" key, the machine platform back to the origin, and then teach the data, otherwise the data is not accurate or can not be taught. Then select the speed grade (1, 2, 3 correspond to low, medium and high teaching speed), press (X+, X-, Y+, Y-, Z+, Z-) key to make the platform move to the first hole point, then press "ok" key to be the first hole point, and then teach the second and third holes and so on.

It is continuous processing products, the middle does not stop, unless the "stop" button, only placed more than 2 jig, toothbrush planting machine to achieve the product cycle processing. Automatic processing can improve the production efficiency, when the processing of the first fixture on the product, the processing of the second fixture on the product, you can replace the first fixture on the product, the processing of the second fixture on the product, you can replace the first fixture on the product, to achieve reciprocating processing. If only one fixture is placed, only semi-automatic machining mode can be used. In standby mode, through the press the number keys on the panel "1", into the automatic way of working, when a protection, whole sets of mechanical action to stop, after repair, move the head to high, use "step" button to find space, and then press the "start" key processing, otherwise the original processed hole position, press the start key processing heavy hole phenomenon will occur and may damage the needle, when it is important to note that when semi-automatic processing, also should pay attention to.

Semi-automatic processing:

Press the "start" button once and process once. After processing the product, the machine head stops at the highest position and runs to the starting point. Replacement products, press the "start" button, once again and run to the first hole, and the processing time, can also start from the first N hole processing to the last hole, N can be set, can through the keyboard input hole number, according to the hole, under Kong Jian run into the hole, make sure that the hole must not processed, and then press the "start" key processing, otherwise it will damage the needle, protection, processing method and the automatic processing.

Automatic test machine of high-speed toothbrush bristler:

After teaching the data of the product, press the button of "up hole" or "down hole" on the full-automatic test screen to realize the one-step hole correction. You can find out whether there is an error in the position of the hole. If there is an error, you can exit and enter the teaching editing interface for modification. Press start and the workbench will move continuously until a product program file has stopped working. This can be used to test whether the workbench is working properly.

Teaching data of hair planting machine

Flocking (drilling machine) walk holes is related with teaching, taught by the data sequence is flocking (drilling) order, after the last hole, back to the first hole, try to make the first and the last hole. A product number contains all hole number (the first hole to the last hole) as a product or a style, or a data file), a product or a design of data can contain several jig, two fixtures (clamp the last hole and the next it's first hole) spacing is called the two hole spacing. The number of the zeroth, known as the starting point or processing zero bits, Not mechanical zero. Must first draw up good planting (drilling) order, in order to ensure speed.

The zero point is the zero point or the starting point

Yangzhou engel automation equipment co., LTD. The main products are: toothbrush planting machine, high-speed toothbrush planting machine, automatic toothbrush bronzing machine our website: www.yzsmsy.com

Address: Tongzhou Road, Hangji Industrial Park, Yangzhou City, Jiangsu Province

Mobile:+86-13952576913

TEL:+86-514-89883136

URL:www.yzsmsy.com