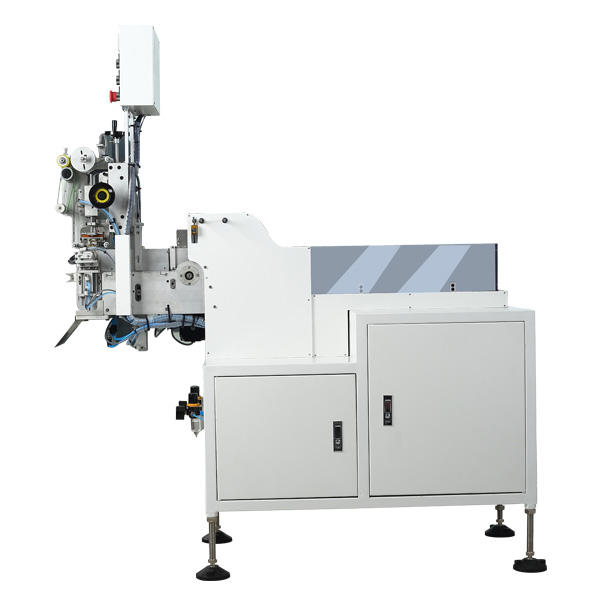

Toothbrush flocking machine, high-speed toothbrush flocking machine, automatic toothbrush bronzing machine

1. The high-speed toothbrush shaper must check the oil, water and brake oil before starting up every day, and warm up for 5 minutes after starting up. During this period, carefully observe the running situation, whether the sound changes, whether there is oil leakage, whether the screws and fasteners are loose, whether the clearance of the sliding frame is too large, whether the electrical instrument shows normal.

2. After drilling, turn on the tail hydraulic air cooler to prevent excessive oil temperature from damaging the hydraulic system.

3. When walking, the drilling barrel shall not touch the ground, so as to avoid damage to the spindle and the transverse shifting frame.

4, the diesel engine two air filter core, air compressor two air filter core must be cleaned twice a day (morning and afternoon each one) more than once, if not clean cause early wear company not three guarantees.

5. After the rig is in the right position, hang the shift rod into neutral and extend the support cylinder before starting the rotary switch, confluent switch and air compressor clutch switch; If the road slope is steep and the drill tires on the triangular-sleepers.

6, after a good position to drill slowly, so as not to damage the drill teeth.

7. When the drilling machine starts to drill down, the hands must not be on the steering wheel, so as not to cause jam caused by moving position.

8. Adjust sliding descent speed and overflow valve according to the geological structure, and the front frame shall not be lifted up when the drilling rig is working (note: when the front frame is lifted up, the pressure is too high, and the overflow valve shall be adjusted).

9. During the operation of the drilling machine, it is necessary to carefully observe whether the slag discharge is smooth and normal. If there is no slag discharge, the drilling barrel should be lifted in time until the slag discharge is completed, and then it will be lowered at a constant speed.

10. Do not lift the drill barrel blindly when it is stuck. Use small jack to cooperate (prevent the deformation of the drill barrel and the bending of the spindle under 5t).

11. Matters needing attention after the completion of drilling, first close the junction switch, then start the lifting switch, drill barrel to the ground no less than 200mm, then open the drilling barrel light and air compressor clutch switch close, close the left and right legs can walk.

12. Before shutdown, let the air compressor run idling for 10 minutes to help the filter cylinder blow back clean and prevent dust from scaling on the filter cylinder.

13. Add butter to 4 grease nozzles on the transmission, 6 grease nozzles on the sliding frame and 2 grease nozzles on the fixed pulley at least twice a day.

14. The rig operator must hold the loader operation certificate before taking up the post.

15. Equipment management implements the system of "two orders and four packages" : the special plane is operated by special personnel, the package is used, the package is kept, the package is maintained and the package is repaired. Require the operator to do three to understand four meetings.

Toothbrush flocking machine, high-speed toothbrush flocking machine, automatic toothbrush bronzing machine

Yangzhou engel automation equipment co., LTD. The main products are: toothbrush flocking machine, toothbrush high-speed flocking machine, automatic toothbrush bronzing machine

Our website: www.yzsmsy.com

Address: Tongzhou Road, Hangji Industrial Park, Yangzhou City, Jiangsu Province

Mobile:+86-13952576913

TEL:+86-514-89883136

URL:www.yzsmsy.com