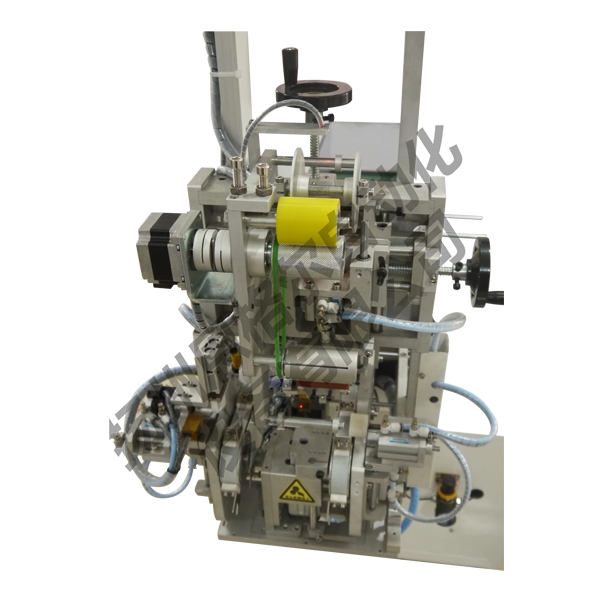

Automatic toothbrush hot stamping machine

Fully automatic toothbrush hair transplanter is equipped with a series of functions such as detection, control, alarm, and man-machine dialogue.Its working efficiency is 2 to 3 times higher than that of semi-automatic hair implanter, and the daily completion volume reaches 20,000 toothbrushes. Market demand has achieved very good economic benefits. The designed full-automatic toothbrush hair implantation machine is mainly composed of 3 parts: a hair implantation mechanism, a high-precision X and Y direction motion platform and a single-chip microcomputer control system.

It mainly completes brush wire transfer, aluminum sheet transfer, aluminum sheet cutting, brush wire and aluminum sheet synthesis, implantation of brush plates, and so on. Its working principle is: starting the spindle motor, which drives the spindle to rotate, and the 3 cams mounted on the spindle start each other at a certain angle. The first cam drive is a reversing device, which drives the pulling bobbin to be drawn back and forth in the bobbin case, so that the toothbrush wire can be continuously fed into the hair implantation mouth; at the same time, another cam drives the aluminum feeding mechanism. The aluminum sheet can be fed into the slicing knife box; at this time, the link mechanism drives the blade to cut out a sheet of 116 mm * 1 mm * 014 mm, and sends it into the hair implant mouth together with the brush wire drawn by the bobbin, and is driven by a stepper motor The workbench equipped with a brush plate for driving is moved under the hair implantation mouth, and a bundle of brush wires and aluminum flakes are implanted into the current brush plate hole to complete a cycle.

This is a very high-precision two-axis positioning system, which mainly completes a series of actions such as toothbrush taking plate, brush plate positioning, X and Y direction displacement, and toothbrush out of plate. Therefore, how this part of accuracy affects the performance of the whole machine and the quality of toothbrush hair implantation requires smooth movement, fast displacement speed, and high in-place accuracy. Generally, the aperture of the brush plate is about 116 mm. To accurately implant the filaments and aluminum sheets into the center of each hole of the brush plate, higher requirements are imposed on the motion platform. The design principle is: the microcomputer controls the stepping motor to drive the X and Y axes, and the X and Y axes use custom precision ball screws. The translational movement of the table is equipped with guide rods on the X and Y axis motion bases, and vertical bearings are installed on the guide rods to eliminate shaking and step errors. Complete the clamping and ejection of the brush plate.

自动烫金机

配置表

气动元件

Address: Tongzhou Road, Hangji Industrial Park, Yangzhou City, Jiangsu Province

Mobile:+86-13952576913

TEL:+86-514-89883136

URL:www.yzsmsy.com